WHAT IS UROP?

NASA’s Illinois Space Grant Consortium (ILSGC) is happy to announce its 21st Undergraduate Research Opportunity Program (UROP) will take place in the summer of 2024. UROP is a program designed to cultivate and support research partnerships between University of Illinois undergraduates and faculty members. All projects focus on NASA-related science and/or engineering research. We want to invite highly motivated undergraduates to apply to participate in UROP.

We envision this program to involve about 20 University of Illinois undergraduate students who will:

- Contribute actively to an intensive research project for 10 weeks (40 hours per week) over the 2024 summer;

- Participate in the weekly seminar series (presentations on research ethics, technical writing, and preparing presentations) organized by the Summer REU committee throughout this summer;

- Write an abstract summary, create a poster, and participate in a one-day symposium to share your research with your peers and any other interested people.

We believe this program provides a unique opportunity for students to become involved in NASA-related STEM research activities.

The selected students will participate in research activities for 10 weeks between May 13 and August 2, 2024, under the supervision of a faculty member and their graduate student(s). Your faculty mentor sets the start and end dates, but we expect you to commit to 10 weeks of intensive research. The program is supported by the NASA Space Grant and faculty contributions. Students will each receive a total maximum of $7,000 in support. Students are expected to participate in the program for approximately 40 hours per week.

Funding will be released incumbent upon authorization of funds by NASA. Placements will not be made until NASA has authorized the funding.

HOW DO I FIND RESEARCH PROJECTS SUPPORTED UNDER UROP?

The research project descriptions submitted by the faculty are listed below.

ELIGIBILITY REQUIREMENTS

- Current student at University of Illinois at Urbana- Champaign

- Highly-motivated undergraduate student

- Provide current transcript

- Provide a current resume or CV

- Complete the online application

WHEN DO I APPLY? WHAT IS THE TIMELINE?

- November 6, 2023 – Student Application Opens

- January 21, 2024– Student Application Closes

- January 22, 2024 – Applicant information/recommendation sent to faculty/mentor

- February 16, 2024 – Faculty/Mentor selections sent to Heidi

- February 23, 2024 – Offer letters sent to students (earlier if possible)

- Students have two weeks from their dated offer letter to accept or decline the offer

- April 14, 2024 – Student stipends and appointments established

- May 13 or 20, 2024 – UROP starts (flexible upon Faculty/Mentor approval)

- July 19 or 26, 2024 – UROP ends (flexible upon Faculty/Mentor approval)

- July 26 – Present your research at the STEM Symposium

HOW DO I APPLY?

The application opens on November 6, 2023

The application closes on January 21, 2024

- Complete and submit the application form.

- All application materials are submitted through the online site; this includes your resume and transcript/academic history. Transcripts/Academic Histories should be PDF documents. You do not have to submit an official transcript, but the document does need to include your GPA.

Completed application form WITH transcripts/academic histories are due by January 21, 2024.

Sometimes, an interview may be arranged between the student and faculty mentor before the final selection is announced.

Program Requirements:

Attend at least 5 of the summer seminar series talks.

Complete the pre- and post-program surveys.

Complete NASA STEM Gateway Registration

Participate and present at the UROP symposium at the end of the summer. Submit a title and create a 10-12 minute presentation or poster on your summer research activities.

As part of NASA’s requirements for awards, UROP students must register on NASA STEM Gateway and participate in Illinois Space Grant’s longitudinal tracking program. Student participants will be contacted for information regarding any publications or proposals resulting from the student’s research experience. This tracking also determines the long-term benefits of the NASA Space Grant Program.

If you have any questions, do not hesitate to contact:

Heidi Bjerke

Senior Coordinator, Illinois Space Grant Consortium

217-300-0151

hbjerke2@illinois.edu

2024 Projects

Adaptive Transportation Management of Air and Ground Logistics for Distributed Energy Supply

Dr. Eleftheria Kontou and Hyunhwa Kim

Civil and Environmental Engineering

Project Description: The proposed research aims to solve the complex energy supply problem with deployed air and ground vehicles in both safe and disrupted environments. The undergraduate research assistants will assist with developing a novel decision-support framework for planning and managing adaptive transportation systems for such multimodal energy logistics. The project sets out to develop optimization models for a bi-directional energy supply logistics network, where electric ground and aerial vehicles can supply backup power to various customers, a practice extremely useful in humanitarian and hazard recovery conditions.

Student Information: The students should have a basic familiarity with optimization models (particularly deterministic ones), facility planning, systems engineering, and scientific computing (having fundamental experience coding in Python).

Number of positions available: 2

Design of haptic interactions in VR for medical training

Caroline Cao and Avinash Gupta

Project Description: Over the past decade, Virtual Reality technologies have undergone rapid development, leading to the creation of VR-based simulation environments across various domains. Although there are several VR based simulators designed for medical training, few provide realistic haptic interactions. Haptic devices and gloves have been shown to be effective in specialized surgical training such as laparoscopy and arthroscopy. However, such devices cannot be used for general medical and surgical training without extensive modification or improvement.

The Jump Simulation Center Urbana – Carle Illinois College of Medicine is taking the lead in creating VR based counterparts to the existing high fidelity physical simulators and mannequins currently used for medical training. The design of effective and human centric haptic interactions will play a key role in the development of such VR simulators. A participatory approach will be utilized for the design of the haptic interactions in which engineers, computer scientists, surgeons, simulation experts and curriculum designers will be involved. The developed interactions will be first validated by experts and further tested by medical students. Based on the feedback of the experts and medical students, the interactions will be enhanced.

This project addresses a critical gap in current medical training technologies, ensuring that VR-based simulations not only represent real-world scenarios but also provide an immersive haptic experience.

Students will work with a team of engineers, computer scientists, surgeons, and simulation designers. Students will use their programming skills to design touch feedback through haptic devices and virtual reality environments on head-mounted displays. Experience with game development engines such as Unity or Unreal is desirable.

Number of positions available: 2

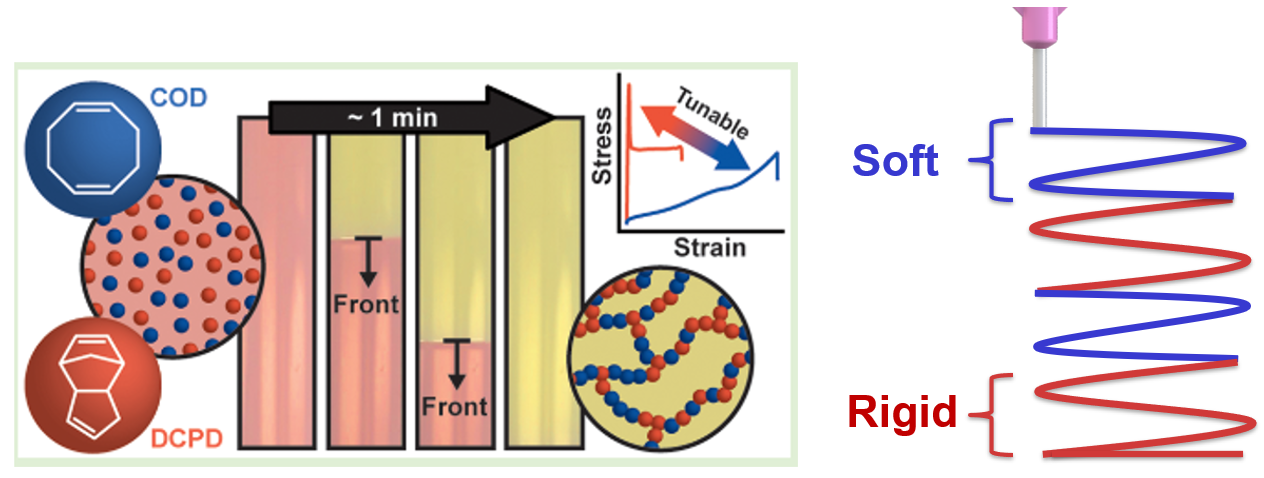

Design of Tunable Polymers for Multi-Material 3D Printing

Dr. Nancy Sottos, Dr. Connor Armstrong, and Pranav Krishnan

Materials Science & Engineering

Mechanical Engineering

Project Description: Frontal polymerization (FP) allows for rapid and energy-efficient fabrication of geometrically complex structures via additive manufacturing (AM, known as 3D printing). This work aims to enable FP AM of complex structures with regions of distinct material characteristics through a combined materials science and mechanical engineering approach. Previously, the Sottos group has demonstrated FP of multi-monomer resins, allowing us to tune material properties through varying ratios of different monomers. This has enabled the creation of simple structures with spatially varied material characteristics including stiffness or elasticity. However, this concept has yet to be applied to 3D printing due to mismatches in “printability” between resins. Printability of a resin is determined by the ability to form a gel and the ability to maintain a polymerization front. We will design new materials for 3D printing by analyzing printability of multi-material resins. The printability trends extracted from this work will inform the control algorithm of the 3D printer.

The manufacturing approach involves the design and operation of a multi-material 3D printing apparatus which will dynamically control monomer ratios for AM. Specifically, dynamic alteration of deposition nozzle speed during fabrication..

Student Information: Seeking enthusiastic undergrads with mechanical and/or materials science backgrounds who have an interest in research. Research focus can be more 3D printing or materials design focused depending on the student’s interest. Previous experience with 3D printing and a basic understanding polymer chemistry/physics are encouraged but not required. Students involved can expect to synthesize frontally polymerizing materials and design characterization experiments. Additionally, students will have the opportunity to work with our custom multi-material 3D printer where they will learn about controls and mechanical systems. The students should feel comfortable handling chemicals and operating 3D printing equipment.

Number of positions available: 2

Gaze-based Immersive Interactions

Dr. Elahe Soltanaghai

Computer Science

Project Description:This project explores a new gaze interaction technique for virtual and augmented reality applications that integrates focal depth into gaze input dimensions, facilitating users to actively shift their focus along the depth dimension for interaction. Familiarity with Unity and some mixed reality programming experience is required for this project. If you’re interested in this project, please take a look at this paper.

Number of positions available: 1

Harnessing Instabilities during Frontal Polymerization for Manufacturing of Architected Materials

Dr. Nancy Sottos and Anna Cramblitt

Materials Science & Engineering

Project Description: Sitting at the intersection of materials science and chemistry, this project will focus on the creation and analysis of architected polymer materials manufactured via a technique called Frontal Polymerization (FP). FP allows rapid, energy-efficient manufacturing of a variety of polymers. Changes in reaction conditions during FP can create instabilities in the system. Depending on the system and reactor geometry used, these instabilities may result in “architected materials” with surface patterning or patterning in the mechanical and optical properties of the resulting polymers.

This project aims to deepen our understanding of the patterns formed via instabilities in FP, explore and characterize new formulations for patterning, and enhance our ability to control pattern formation. Techniques such as IR imaging, DSC, optical and/or confocal microscopy, NMR, and Raman Spectroscopy can be used to observe and analyze pattern formation and understand the effects on material properties. X-ray scattering and mechanical characterization through nanoindentation or DMA may also be used. Day-to-day activities will include preparing samples for DSC, performing limited organic synthesis, mixing new monomer formulations, preparing patterned samples while recording the polymerization reaction with an IR camera, and analyzing data.

Student information: Interested students should have a background in Materials Science & Engineering, Chemistry, Chemical Engineering or similar, with a basic understanding of organic chemistry/polymer chemistry. Familiarity with the concepts behind common polymer characterization methods such as DSC, DMA, NMR, TGA, and/or mechanical property testing is preferred.

Number of positions available: 1

How do bats respond to forest management?

Dr. Joy O’Keefe, Reed Crawford and Katie Fitzgerald

Natural Resources and Environmental Sciences

Project Description: Most bats in the Midwest rely upon forests for roosting and foraging habitat. The remaining large tracts of forest are often on state or federally owned land and are managed for a variety of uses, including for timber products and for wildlife habitat. Harvesting forests for timber or to provide optimal wildlife habitat could have unintended negative effects on bats that require forested habitat but harvesting could also be beneficial. The goal of our research is to study bat responses to timber harvest, which allows us to make management recommendations to natural resource managers with state and federal agencies. Students hired onto this project will gain experience with capturing bats, using radio telemetry to locate bat roosts and foraging sites, and using other technology such as automated recording units or datalogging receivers, to study bat ecology. Students will live and work in a remote location in either Indiana or Missouri and will work collaboratively with a team of researchers during the period of mid-May to mid-August 2024.

Student Information: Students should have a background and strong interest in natural resources. Experience working outdoors, hiking, and being active at night are essential. Students should be team players, good communicators, organized, and pay attention to details. A valid driver’s license is very helpful.

Number of positions available: 2

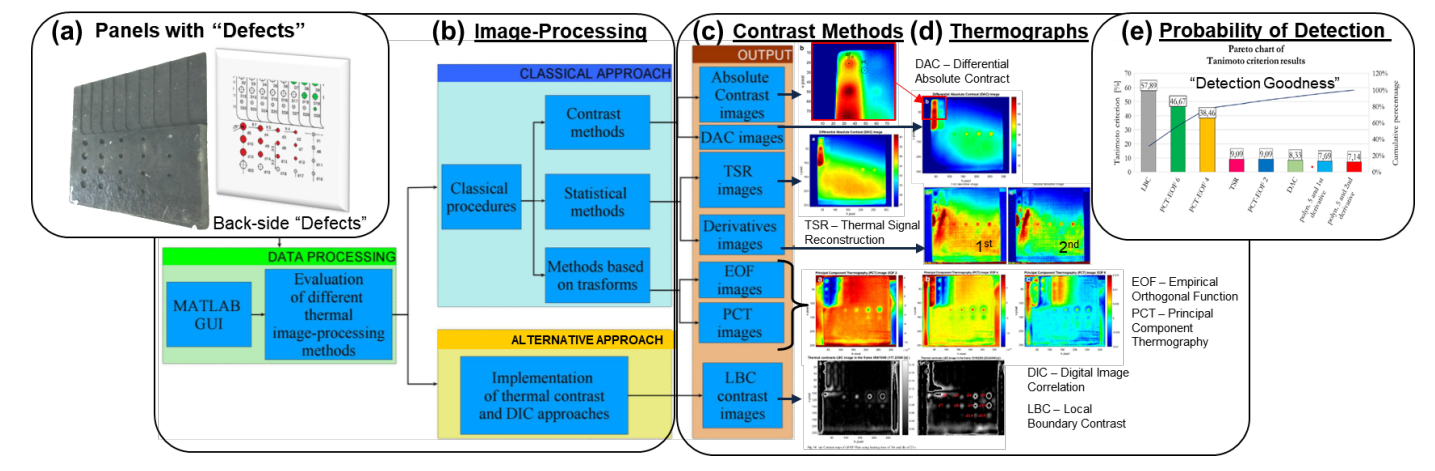

Multifunctional Composite Structures with Damage Sensing Capabilities

Dr. Jeff Baur and Ivan Wu

Aerospace Engineering

Project Description: The work involves manufacturing composite tubes/beams with embedded heaters using the newly acquired Continuous Fiber 3D printing machine acquired from Continuous Composites Inc. The goal is to develop composite structures such that if the composite is damaged in space due to debris impact or radiation, the embedded heaters can re-activate dormant monomers to self-heal the composite. Additionally, with the use of thermography, we hope to develop an algorithm that can inform us the structure damages of the composite with IR images of the composite. From this information, the heaters can locally heat the structures for self-healing purposes.

Student Information: The student will work on rapid prototype of components to help with the manufacturing process. As such, the student should have an understanding of CAD and FDM printing. The student should also have a surface knowledge of electronics and circuits as we will be working with resistive heaters and other automation software to help with the manufacturing of composites.

Student will also explore the possibility of using the thermal signature generated externally (through passive uniform heating) or internally (through active Joule heating of embedded conductive wires) at the surface of the composite structure to infer the location, size and shape of internal damage.

As such, any previous experience with composite manufacturing and mechanical testing is preferred.

Number of positions available: 1

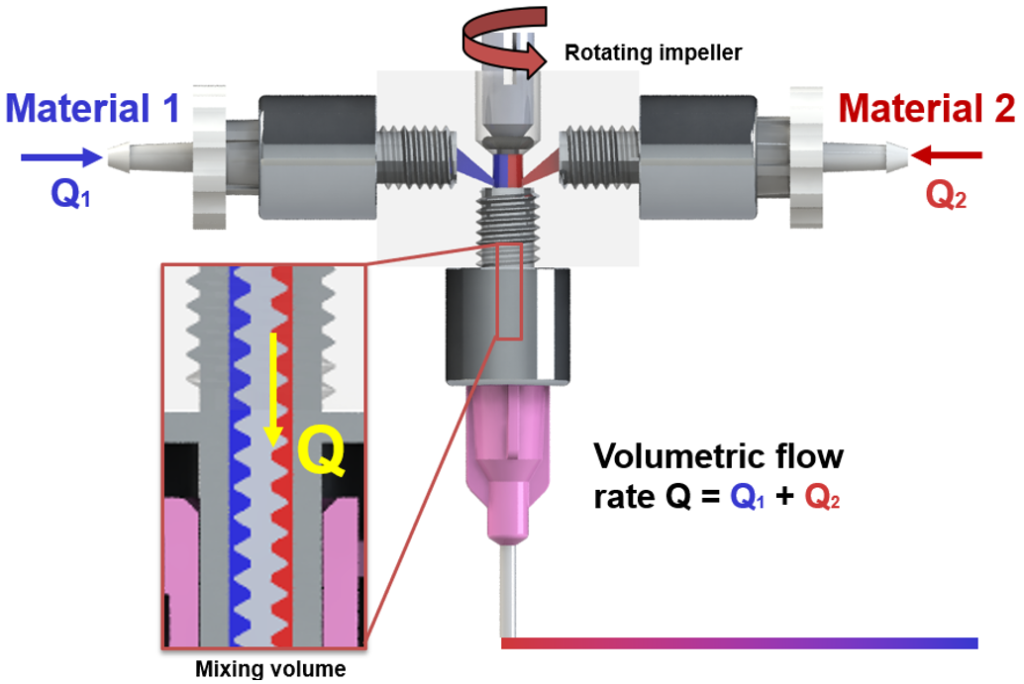

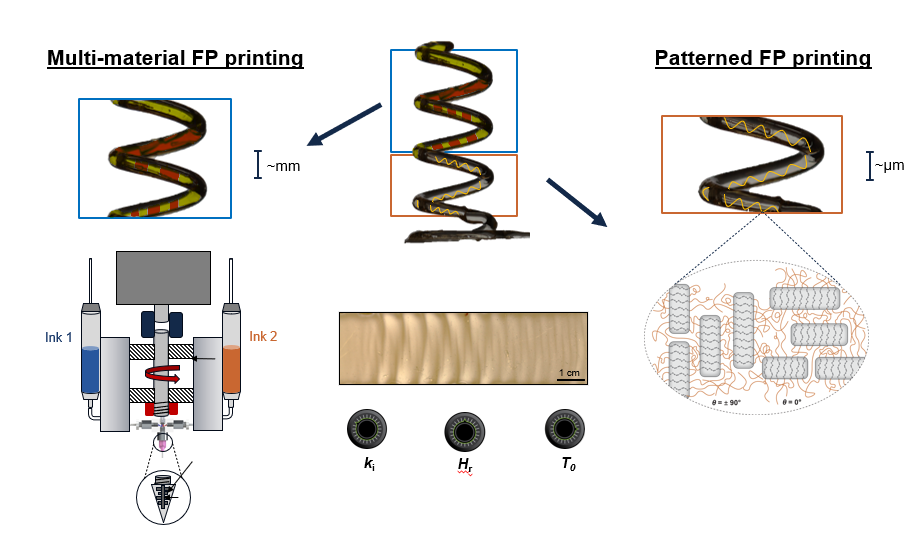

Multi-scale Morphology Control of 3D-Printed Structures using Frontal Polymerization

Dr. Sottos and Pranav Krishnan

Materials Science and Engineering

Project Description: My research focuses on developing materials for 3D-printing sustainable and strong engineering polymers for applications in the energy and aerospace industries. Our lab works with a novel energy-efficient manufacturing process called Frontal Polymerization, that allows us to fabricate tough thermoset polymers and composites with a very small energy input.

My goal is to derive inspiration from nature to design 3D-printed materials and structures that are morphogenic (have hierarchical microstructures and patterns that enhance their structural and functional properties). We will work to create this material morphogenesis by harnessing intrinsic instabilities in the frontal polymerization process. These lead to phenomena like crystallization or phase separation that give controlled gradients in material properties on the scale of micrometers.

Zooming out, we aim to also have controllable material property gradients on the scale of millimeters using multi-material printing. Via a custom-built printhead that incorporates active mixing of multiple monomer materials, we will be able to tune the composition of our inks for printing on-the-fly. An example of this is to have different mixtures of stiff thermoset and soft elastomer inks, to have regions of varying stiffness 3D printed within the same structure. Incorporating these multi-scale gradients in 3D printed structures using Direct-Ink Writing can open up a wide range of high-performance structural and functional applications.

Student Information: An undergrad would be involved in the material synthesis, characterization and data analysis, as well as 3D printing or mechanical testing if they are interested. Materials chemistry will compose a large part of the project, exploring new chemistries and their ability to develop morphogenic properties during 3D printing. Materials characterization tools such as Differential Scanning Calorimetry (DSC), Shear Rheometry, and Dynamic Mechanical Analysis (DMA) would be in use – students will be trained on these techniques. A background in Chemistry, Materials Science or similar is preferred, or prior research experience in a chemistry lab environment.

Students who are looking to apply to graduate school in the future and are interested in longer-term research projects that will continue past the summer will be given preference.

Number of positions available: 1

Radar-based Environmental Sensing

Dr. Elahe Soltanaghai

Computer Science

Project Description: This project explores the use of radar for sensing the under-canopy layers of the forest such as soil or biomass moisture. The research activities include the use of signal processing and machine learning for estimating water content from wireless reflections. Required expertise: Python programming, signal processing, and deep learning. If you are interested in this project, review this paper (https://dl.acm.org/doi/pdf/10.1145/3300061.3345440).

Recyclable Thermoset Composites for Aerospace Applications

Dr. Jeff Baur and Saurabh Bagare

Aerospace Engineering

Project Description: Frontal Ring Opening Metathesis Polymerization (FROMP) enables energy efficient manufacturing of thermoset polymers and composites. However, the end-of-life strategies of these engineering materials is still a question that remains to be answered. Imagine 30 years down the line where we have composite aircraft and spacecraft structures that are at the end of their service lives. They would just exist on the surface of the Earth and increase the carbon footprint.

We have demonstrated, that by using something called cleavable crosslinkers in the resin matrix, we can chemically deconstruct a thermoset composite and retain the fibers back, which can then be used for the next generation lifecycle. The challenge being, is the composite still worthy of aerospace applications?

This project involves manufacturing, analysis, and characterization of deconstructable thermoset polymers and composites using cleavable covalent crosslinkers. We aim to perform thermomechanical tests to see how the composite, or the polymer compares to the currently used thermosets, and find ways to either equate, or exceed the state of the art. We will also study how the material behaves, or changes, when exposed to real-life conditions like heat, oxidation, UV exposure, and mechanical wear and tear. The quality of the results will be assessed and then considered for high impact Journal Papers and Conferences, thereby sharing it with the greater scientific audience.

Student Information: As an undergraduate student, you will be involved in manufacturing, testing, characterizing, and analyzing the thermomechanical properties of various deconstructable thermoset polymers and composites, that are manufactured through frontal polymerization. You will be able to independently form the test matrix and observe how the objective variables like the resin chemistry, initiation temperature, mechanical load affects the various parameters of the material like fiber volume fraction, ultimate tensile strength, and deconstruction.

Because the project is highly experimental in nature, the student is expected to learn and adhere to all the lab safety instructions and protocols of a chemistry/materials lab. The student must physically be present in the lab and conduct experiments. There is no scope for remote work here. This also means that the student will get access to some of the most extensive materials research facilities, which happen to be on the college campus! The student can expect to work on synthesis and characterization. Studying the properties of different combinations of materials, manufacturing them, then discussing with the greater audience through collaboration is something that we will be doing almost every day.

Number of positions available: 1

Seismic and Electrical Geophysics to Find Boundaries of Glaciofluvial Aquifer in East Central Illinois

Jason Thomason, Riley Balikian, and Kisa Mwakanyamale

Project Description: Student(s) will acquire geophysical data in the field and carry out basic processing of geospatial and geophysical data. This includes a significant amount of time outside in the summer heat doing fairly labor-intensive work. It will also include time doing processing of geospatial data using geographic information systems (GIS) software and may include processing of seismic data and some electrical data, depending on background and training of student. The exact research project(s) will depend on the interest of the student(s) but have in the past included synthesis of multiple datasets to delineate aquifer boundaries in 3D, comparison of ambient seismic (HVSR) datasets to existing data, and spatial analysis of existing well and 1D data to determine subsurface (hydro)geologic properties at specific sites. Student(s) will be trained on software, skills, and geologic background, and geophysical techniques. Student(s) will be part of a team of 1-4 other students.

Student Information: Much of the time will be spent acquiring data in the field, so student(s) will need to have the ability to carry equipment in field conditions. Travel to/from sites is taken care of by ISGS/PRI. When not in the field, student(s) will analyze data in a geographic information system (GIS) software and software specific to the geophysical method. Basic knowledge of geospatial data and earth sciences is preferred. Background in python will help with data processing but is not required. Subject matter includes seismic geophysics (acoustic waves) and electrical geophysics.

Number of positions available: 2-4

Study of Spatial Visualization Training Effectiveness for Engineers

Dr. Brian Woodard

Aerospace Engineering

Project Description: Decades of research involving many thousands of participants has consistently shown that spatial skills are one of the strongest predictors of future success in STEM coursework and STEM careers independent of math and verbal ability. Fortunately, research also shows that visuospatial skills are malleable, and individuals may need different methods to practice and improve their skills. For example, a series of studies showed that gender differences in STEM education could be reduced by enhancing visuospatial skills through computerized training that involves different forms of practice in solving visuospatial problems.

Based on this background information, The Grainger College of Engineering has been offering an elective spatial visualization training course for first-year students since 2019. Data have been collected regarding these students’ spatial visualization abilities before and immediately after the course. Additionally, a large dataset is available showing the long-term impact of the training course on these students’ success in their subsequent STEM courses. Data organization, analysis, and visualizations are needed to investigate and publicize these efforts, illustrating the impact of this particular course and the importance of spatial visualization skills more generally in STEM.

Student Information: A successful student for this project will have an interest in Engineering Education research. Skills with programming for organizing datasets and creating visualizations are required. Experience with CAD (preferably NX), a rendering program like Blender, and other visualization programs (like Photoshop, Inkscape, etc.) are also beneficial.

Number of positions available: 1

Tailored Interfaces in Frontally Cured Fiber-Reinforced Thermoset Composites

Dr. Nancy Sottos and Tyler Price

Material Science & Engineering

Project Description: Frontal curing is a rapid, energy-efficient manufacturing process for producing high volume fraction thermoset

composites. In frontal curing, the heat generated from an exothermic reaction is sufficient to overcome losses to

the environment and reinforcement, allowing a self-sustaining linear front to propagate through the material and

rapidly convert liquid monomer into solid thermoset polymer matrix. In this work, we utilize continuous carbon

fiber reinforcement and frontally cure a matrix of dicyclopentadiene (DCPD) with Grubb’s second-generation

catalyst and a phosphite inhibitor.

We evaluate the strength of the interface formed in frontally cured carbon/pDCPD composites using the single

fiber fragmentation test (SFFT). In SFFT, a tensile specimen with a continuous, stiff reinforcing fiber parallel to

the loading axis is incrementally loaded to repeatedly fracture the fiber. We use birefringence to observe the

fiber’s fragmentation until the number of fragments saturates. The number and length of fragments at saturation

is related to the interfacial shear strength through a shear lag analysis. Ongoing work seeks to improve the

interfacial adhesion in frontally cured carbon/pDCPD composites to match the performance of traditional high-

performance carbon/epoxy composites.

As an undergraduate research assistant, you will participate in the

design, manufacturing, testing, and analysis of frontally cured composites. You will observe how engineering

(e.g. pre-tension, pre/post-cure cycles) and chemical (e.g. comonomers, fiber treatment) approaches impact their

manufacturability and interfacial strength. In addition, you will characterize properties of the composite that are

influenced by interfacial adhesion such as short beam interlaminar shear strength.

Student Information: We are seeking a student who is interested in learning about composite interfaces, mechanical characterization

and polymer composite manufacturing. Experience with LabVIEW and a background in polymer science are

preferred, but not required. The student should be comfortable handling chemicals and operating mechanical

testing equipment and optical microscopes

Number of positions available: 1

Turbulence and metamaterials: fluid-structure interaction for flow control

Dr. Theresa Saxton-Fox, Elizabeth Torres De Jesus and Nissrine Aziz

Aerospace Engineering

Project Description: Students will help design and execute experiments to study the fluid-structure interaction of turbulent flows passing over solid surfaces that are designed to respond in unusual ways to the fluid. We will understand how the fluid and solid motions can be coupled and how we can use that coupling to reduce flow disturbances.

Student Information: Knowledge of CAD may be useful, as students may need to help design new testing configurations. Some background in solid and fluid mechanics is helpful but not a requirement. Willingness to work independently and a strong ability to problem solve are very helpful.

Number of positions available: 2

Visualizing Invisible Wireless Signals

Dr. Elahe Soltanaghai

Computer Science

We are developing a mixed-reality app that can visualize wireless signals between WiFi devices in homes and buildings and their interaction with objects and people in the environment—desired expertise: blender, unity, familiarity with LiDar and Mesh reconstruction algorithms. If you’re interested in this project, please take a look at this paper (https://meghanclark.com/uploads/papers/clark21xrshark.pdf).

Number of positions available: 1

Estimating Hybrid-Electric Aircraft Emissions over Lifecycle

Dr. Elle Wroblewski

Aerospace Engineering

- Python

- Understanding aircraft emissions

- Understanding commercial air travel

- Mathematics Competancy

SIMULATED EXPERIMENT ON A COMPUTER INVOLVES: - Work on extending the capabilities of a collaborator’s program which

calculates aircraft emissions over missions - Use simulated hybrid-electric aircraft performance predictions to evaluate

viability of aircraft with sustainable retrofit drivetrains - Validate predictions with literature and data

- Debugging code

- Validating changes to code

- Student-suggested topics of investigation

RESEARCH TOPIC AREAS – LEARNING AREAS - Programming

- Aircraft emissions in atmosphere and during taxi

- Aircraft routing and airport infrastructure

- Electrical power draw and powerplants

- Regional air infrastructure

- Climate impact investigation

- Aircraft emissions estimation, electric grid emissions estimation

- Statistics

- Technical writing

- Debugging

- Time management

Number of positions available: 1